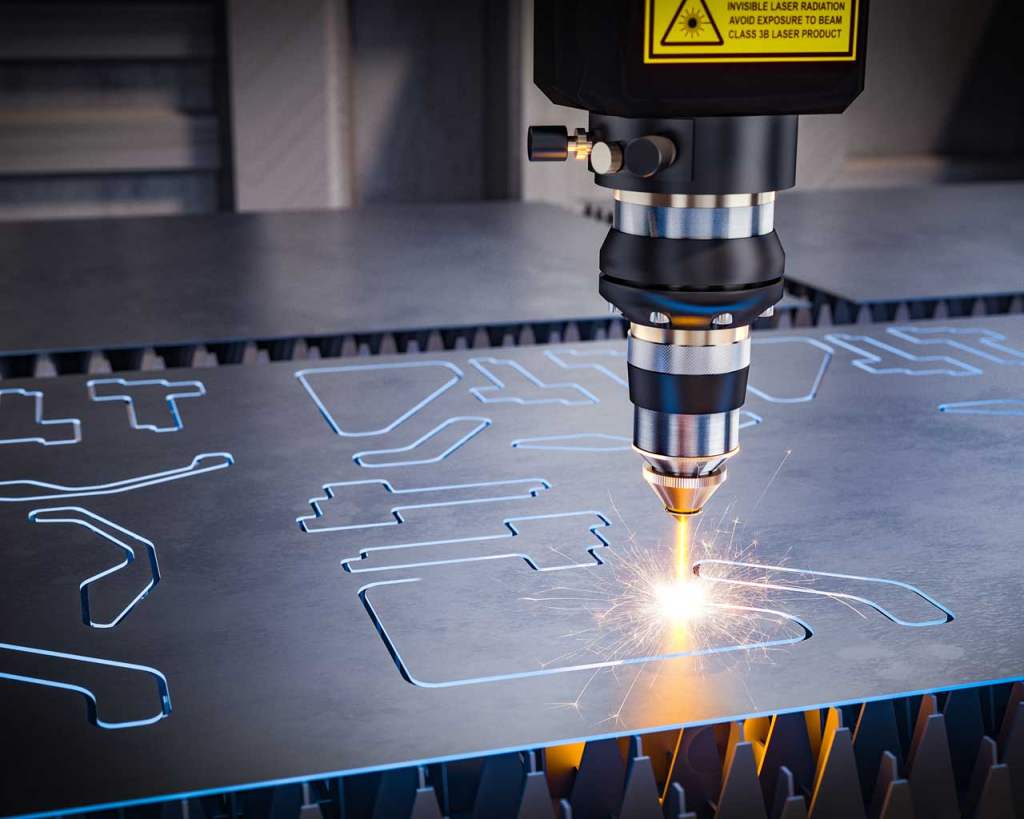

Laser chopping solutions have appeared since the pinnacle of detail on the planet of manufacture and design. Using the power of concentrated supports of gentle, laser cutting is a scientific miracle that brings unparalleled accuracy and versatility to an array of industries. In that exploration, we delve in to the complex earth of laser cutting solutions, knowledge their applications, advantages, and the major affect they’ve on the realms of production, design, and beyond.

At the core of laser chopping lies the capability to obtain pieces of remarkable detail, enabling the creation of complicated models and complicated styles that have been after difficult to accomplish through standard chopping methods. The laser beam’s concentrated depth permits minimal product wastage, ensuring efficiency and cost-effectiveness in production processes. That detail extends to a diverse array of materials, including metals, plastics, timber, textiles, and more, making laser chopping a functional alternative for various industries.

The advantages of laser chopping are manifold, specially in manufacturing. The procedure permits the quick prototyping of patterns, facilitating rapid iterations and adjustments. This agility is priceless in industries wherever time-to-market is a critical factor. Furthermore, laser cutting provides for the manufacturing of very detail by detail parts with smooth ends, causing the entire quality and operation of the conclusion product. From automotive components to elaborate digital parts, laser cutting is becoming crucial in the production landscape.

One of the standout features of laser chopping services is the ability to work with a varied selection of materials. Laser blades can effortlessly portion through materials, offering detail in programs like sheet material manufacturing and elaborate material artwork. Simultaneously, exactly the same laser cutter may softly etching intricate styles on fine resources such as for instance report or fabric, showcasing the flexibility that models laser chopping besides conventional cutting methods.

The affect of laser cutting stretches beyond production to the realms of style and creativity. Musicians and developers influence laser chopping services to breathe life into their ideas, creating detailed sculptures, architectural models, and bespoke parts that force the boundaries of what’s achievable. The finesse with which laser cutters manage components allows for the conclusion of elaborate habits, customized engravings, and three-dimensional patterns, checking new possibilities for innovative expression.

In addition to precision, laser cutting services provide effectiveness and speed. The non-contact nature of the process eliminates the requirement for physical tool improvements, reducing downtime and enabling continuous and uninterrupted cutting. That performance is specially essential in large-scale generation, where rapid recovery times are crucial for conference market demands.

The introduction of laser chopping has additionally ushered in a fresh time of modification and personalization. Whether it’s developing delicate patterns on wedding invitations or producing unique signage for businesses, laser cutting services enable individuals and companies alike to impress a touch of personalization to their Tube bending . The engineering makes for the conclusion of elaborate and comprehensive styles with consistency and repeatability, ensuring that every bit is a function of accuracy and artistry.

In conclusion, laser chopping solutions signify a peak of detail, flexibility, and efficiency in the realms of production and design. From the formation of complex components in industrial adjustments to the realization of creative ideas in creative spots, laser cutting is now an fundamental tool. The relationship of technical complexity and creative freedom makes laser cutting solutions a transformative force, unlocking new possibilities and placing new criteria of detail on earth of fabrication and design.